HongJun

Cold pressed terminals belong to the category of connectors and are the link connecting wires and equipment in the operation of electrical equipment. With the refinement and development of industrial control and electrical power, more and more cold pressed terminals are installed on the equipment. What should be paid attention to when using cold pressed terminals

1、 Fully understand the cold pressed terminal to be operated and be familiar with its operation method to ensure correct operation; Cold pressed terminals without anti misoperation shall be identified by color code or mark, or whether the appropriate model corresponds before connection, and ensure correct positioning during mutual connection; Special attention shall be paid to prevent the wrong insertion of socket with pin, otherwise the cold pressed terminal will be damaged and accidental electrical contact will be caused; It shall be ensured that the cold pressed terminals are connected in place. In special occasions that are not easy to check, detailed provisions shall be made in the corresponding operating procedures, and can be checked through the endoscope

2、 When cold pressed terminals are terminated, they shall be terminated and checked in strict accordance with the corresponding termination specifications or requirements, and terminated according to the corresponding node serial number. The maximum insulation layer thickness between the selected cable conductors shall match the spacing between the contacts, and the cable core shall match the terminal of the contacts. When the contacts are crossed and parallel, it shall be treated

3、 During welding, the electric soldering iron with corresponding power shall be selected according to the diameter of bare wire. The welding time of each contact shall not exceed 5S. Pay attention not to allow the flux to penetrate into the insulator, so as not to reduce the insulation resistance of the product

4、 When the cold pressed terminals are in the separated state, protective caps shall be installed or other dust-proof measures shall be taken; If the cold pressed terminal does not separate for a long time after connection, a fuse can be placed between the plug and socket

5、 When cleaning the cold pressed wiring terminal, use silk cloth dipped in absolute ethanol and use it after drying. Acetone and other chemical solvents that may have harmful effects on the connector are not allowed

6、 When connecting or separating the cold pressed terminal, try to make the axis lines of the plug and socket coincide, and straighten the cable to prevent the plug from being affected by tangential force and the connector from being damaged due to cable sagging

7、 Do not energize the cold pressed terminal until it is properly connected or fully locked

8、 In the fixing of cold pressed terminal, clamping of harness and other occasions, there shall be anti loose devices (anti loose screws, anti loose rings, fuses, etc.) when using threaded connection

9、 The acceptance and inspection of cold pressed terminals shall be carried out according to the requirements of relevant product standards and operation instructions. The acceptance and inspection of used electrical connectors shall be carried out on the basis of relevant product standards and operation instructions, and the cold pressed terminals of tooling used shall be intact and qualified; The probe shall meet the standard requirements, otherwise it is easy to cause Jack damage

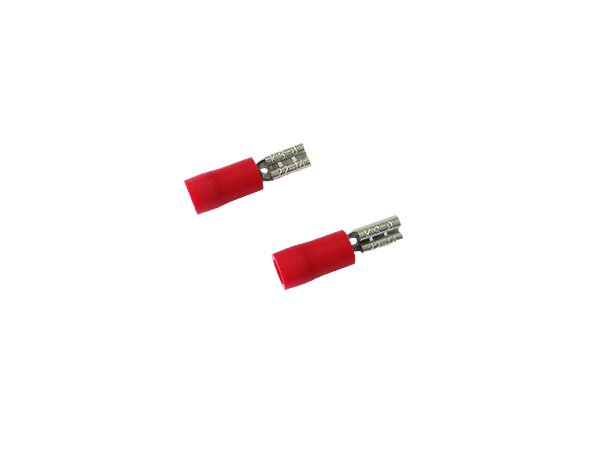

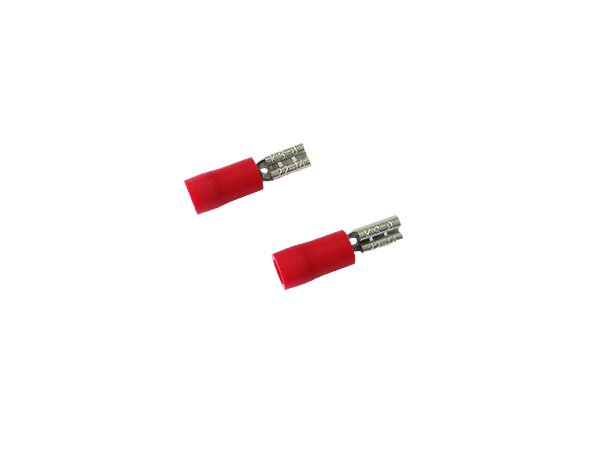

Cold pressed end, also known as "industrial rice", is ubiquitous in the field of electrical connection. Standardized use and frequent maintenance can play a great role in the operation of electrical equipment; If the installation is not standardized, it may also cause short circuit and open circuit of the equipment, which may damage the electrical equipment. The cold pressed terminal in this paper is also known as wiring nose and copper nose. The product shape can be divided into O-type and U-type. At the same time, there are also differences between products with insulating sleeve and products without insulating sleeve